Experienced OxiMax MC Series Experts Based in Australia

The OxiMax MC Series

Description

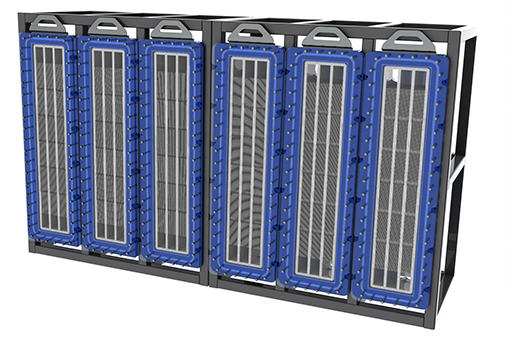

The OxiMax MC Series is designed to produce Sodium Hypochlorite (NaOCl) from seawater or water with salinities > 4 g/l. These heavy duty, high performance cells use Thermomoulded PVC casings and bipolar electrode arrangements for optimum energy efficiency, safety and NaOCl production.

Typically, a side stream of seawater is taken from the discharge of the seawater pumps directly to the Electrochlorination Plant. This seawater is strained to 400 micron and passed into the electrolyser cells. DC power is applied to the seawater inside the cells which results in the production of Hypochlorite.

The OxiMax MC Series uses staged Hydrogen removal through the electrolyser train via multiple Hydroclones, resulting in superior Hypochlorite production and energy savings. The Hydrogen flows to the Hypochlorite storage / degassing tanks where the Hydrogen is diluted to < 4% (typically < 1%) and safely purged to atmosphere.

The Hypochlorite is then dosed into the seawater intake lines to prevent marine growth and biofouling of the mechanical equipment such as the cooling water pumps, the bar screens, drum screens and condensers as well as the cooling water pipelines of the power station.

Each OxiMax MC Series system is controlled by a high quality PLC with a colour HMI, for ease of control.

Read More

Applications

Power Stations, refineries, Industrial complexes, seawater swimming pools and Water Parks are ideal applications for the OxiMax MC Series Electrochlorination Systems.

Advantages

- See every Anode and Cathode

- Complete biofouling and marine growth control

- Cells are fully insulated – no exposed DC busbars or electrical connections for

- greater personnel safety

- Staged hydrogen removal for increased efficiency

- Cost effective and reliable

- Low maintenance and easy cell removal for maintenance

- Completely automatic Sodium Hypochlorite (NaOCl) production

- Safe, reliable and robust

- Modular configuration

- Forced air hydrogen gas dilution and purging

- 5 Year Warranty on electrodes

- SC12 MMO Coatings on Anodes for increased efficiency

- Integral Voltage Monitoring

- High flow velocity waterways reduce energy consumption and minimise the need for acid cleaning.

- Highest efficiency design = Lowest operating cost

- Hypochlorite outputs up to 400 kg/hr

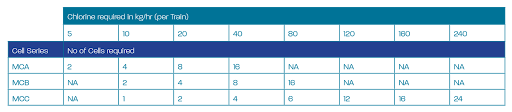

OxiMax MC Series Electrochlorination System Sizing

A typical OxiMax MC Series system consists of some or all of

the following:

- Seawater Booster Pump(s)

- Seawater Auto Backwash Strainer(s)

- DC Transformer Rectifier(s)

- Staged Hydrogen separation

- Continuous and Shock Dosing Pump(s)

- Hydrogen dilution Air Blowers

- Storage / degassing Tank(s)

- Control System (PLC/HMI)

- OxiMax MC Series Electrochlorination Cell(s)

- High Quality Instrumentation – flow, temperature, pressure, level.

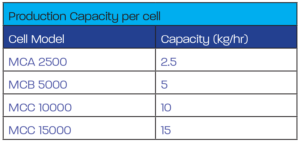

OxiMax MC Series Electrochlorination System Sizing

We use the MCA, MCB or MCC cells as the basic building blocks to form an entire OxiMax MC Series electrolyser train (MCC60000 = 60kg/hr shown)