OxiMax MA Series Specialists in Australia for Water Systems

The OxiMax MA Series

Description

A Water Booster Pump (if required) increases the pressure of the incoming water to allow it to flow through a Water Softener and Chiller (if required). A Brine Pump supplies saturated brine at a controlled flow to mix with the water. The dilute brine solution flows through the MA Series Electrolyser Cells where DC current and voltage is applied. The current passing through the water causes the dissociation of NaCl (salt) and H20 (water), allowing the formation of Hypochlorous Acid (HOCl) and Sodium Hypochlorite (NaOCl) with Hydrogen gas (H2) as a by-product. The solution flows to a Radar level controlled Hypochlorite Storage Tank where the Hydrogen is safely vented to atmosphere by Duty / Standby Ventilation Fans. Dosing pumps distribute the Hypochlorite solution to the water to meet the required Chlorine demand.

Read More

Applications

Typical applications are potable and waste water treatment plants, industrial plants, water parks and large swimming pools.

These heavy duty, high performance cells use Thermomoulded PVC casings and bipolar electrode arrangements for optimum energy efficiency, safety and NaOCl production.

Advantages

- See every Anode and Cathode

- Fully insulated – no exposed DC busbars or electrical connections for

- greater personnel safety

- Cost effective and reliable

- Low maintenance simple cell removal for efficient electrode refurbishment

- Completely automatic Sodium Hypochlorite (NaOCl) production

- Skid mounted for easy installation

- Modular configuration

- Forced air hydrogen gas dilution and purging

- 5 Year Warranty on electrodes

- SC12 MMO Coatings on Anodes for increased efficiency

- Integral Voltage Monitoring

- Safe, no hazardous chemicals to transport or store

- Consistent Hypochlorite strength and quality

A typical OxiMax MA Series consists of some or all of the

following:

- Brine Saturation Tank

- Brine Pump(s)

- Fresh Water Pump(s)

- Water Softener(s)

- DC Transformer Rectifier(s)

- OxiMax MA Series Electrochlorination Cell(s)

- Control System (PLC/HMI)

- Hydrogen dilution Air Blowers

- Radar level-controlled Hypochlorite Storage Tank(s)

- Dosing Pump(s) and Dosing Control

- High Quality Instrumentation – flow, temperature, pressure, level.

- Chiller(s).

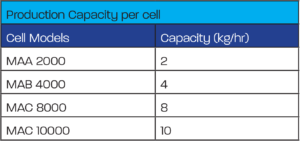

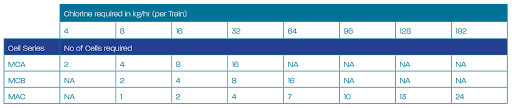

OxiMax MA Series Electrochlorination System Sizing

We use the MAA, MAB or MAC cells as the basic building blocks to form each OxiMax MA Series electrolyser train (MAB12000/3 = 12kg/hr shown)

Chart to be revised.